.jpg)

UV flatbed printers are becoming more and more popular in the market. However, some customers feedback that after using a long time, the small letter or picture will be blurred, not only affect the printing effect, but also influence their own business! So, what should we do to improve the printing resolution?

Here we should know the reasons as below:

1. The image itself with lower pixel.

2. The encoder strip and the encoder sensor are dirty.

3. The X-axis guide rail does not slide smoothly and the friction is large.

4. The drive parameters of x-axis and y-axis are wrong.

5. Output accuracy of the uv printer is not high.

6. The distance is little higher from printhead to material surface.

Solutions:

1. Choose high-precision image to print. To be frank, UV printing is the process of input and output. Input is the process of inputting data from the computer to the printer. If the accuracy of the input image itself is not high resolution, no matter how high-end the uv printer is, it cannot change disadvantages of the input image itself.

2. Use a non-woven cloth with alcohol to wipe encoder strip until it is completely cleaned. If necessary, clean the encoder sensor together.

3. Use inks from original supplier of your printer. Although there are many inks on the market and their prices are cheap, their fusion degree and purity are poor. After printing, ink dots are uneven and blocky. Therefore, it had better use high-quality ink from the original manufacturer of your printer. If the printed font is still blurred, you can check whether the print head is clogged. If the nozzle is clogged, do not disassemble it by yourself. Please contact the manufacturer to get some suggestions.

4. Print head alignment. Check the wire of the ink supply tube to avoid collision between the ink tube and the mechanical part of the printer. And make sure the head align perfect (ajust from horizonal,vertical,uni-direction,bi-direction,etc)

5. The output accuracy of the UV flatbed printer, that is, the printing accuracy, a direct expression of the quality of the mainboard, ink supply system and the printhead. Maybe you need to change a new head.

6.For flatbed ERICK 6090UV printer, please keep 2-3mm distance from head to materials surface during printing.

With our Erick UV flatbed printer, you can print on almost all kinds of flat materials such as arcylic, ceramic tile, paper,PVC board, metal etc. Sometimes maybe your customers want to get a embossed effect such as braille alphabet.For this demand, when need to know how UV printer get embossed effect.

After curing the UV ink by UV lamp while printing, all colors will has their own thickness,normally dark areas of picture will get a little more thicker than light areas. so we can get embossing-effect by printing plenty UV inks, but at now we will have a problem like this: after printing several times of color ink,it will cause that we can’t get the ture color of image file. so we use white ink to solve this problem.

We can repeat white ink several times as substrate, with more repetition times,the thickness of white ink will more thicker,then only need to print color ink on the substrate.

So for our Erick UV printer,only need to follow these steps below:

(1) send the image file into PRT format file from Photoprint;

(1).jpg)

(2) load PRT file into PrintExp and set the repetition times, you can set as 2,4 or 8 times.

(3) print out on materials.

There’s another purpose of white ink: when we print on some kinds of materials their surface not white,just like glass or metal, at now we need to print white ink as substrate firstly,then print color ink out.If you print color ink on these materials directly, you can’t get ture color either.

.jpg)

Firstly, good working environment:

1.Temperature and Humidity: Keep the temperature at 18-28℃, especially in winter. And the humidity usually at 30-50RH.

2.Ray of light: UV ink will be cured when exposed to light, so we must ensure that there is no strong light in the room.

3.Wind. Most workshops have fans in summer, the fans will accelerate the air flow then the head is easy to dry, finally clog.

4.Clean. If the workshop is full of dust, the particle may adhere on the nozzles then clog.

Secondly, proper operation:

1.Please notice the height of materials before printing. Many customer forgot to adjust height after changing material, then the printhead damage directly due to carriage cash. Erick UV printer have auto altimetry system which is convenient and helpful.

2.Nozzle test everyday before printing, if there is some nozzles missing, please clean in software immediately. If you found the head is clogged seriously, please clean gently and softly with syring. ( Why gently and softly? Higher pressure may break the head and cause ink mixing.) Please note that never dip the whole printhead in cleaning liquid!

3.Keep printhead cable clean. Once the cable is dirty(especially the metal port) , the head may be burned.

Tips: Most heads damaged are not for lifetime, but for improper cleaning. Suitable way of sucking ink can extend the printhead life. For cleaning operation, please contact with us to get tutorial video.

1.If printer with capping service, you just need to keep the nozzle connect well with the capping. Our Erick UV printer adopt lifting capping station which can make sure well-sealed to prevent the air-dry or dust. You can also put some cleaning liquid or moisturizing liquid on capping for long period(such as 3-7days) inactivity.

2.If printer without capping service, you can put some cleaning liquid on non-woven fabrics and then keep the carriage on it. Please keep inspection and filling cleaning liquid each two days to avoid the nozzle dry.

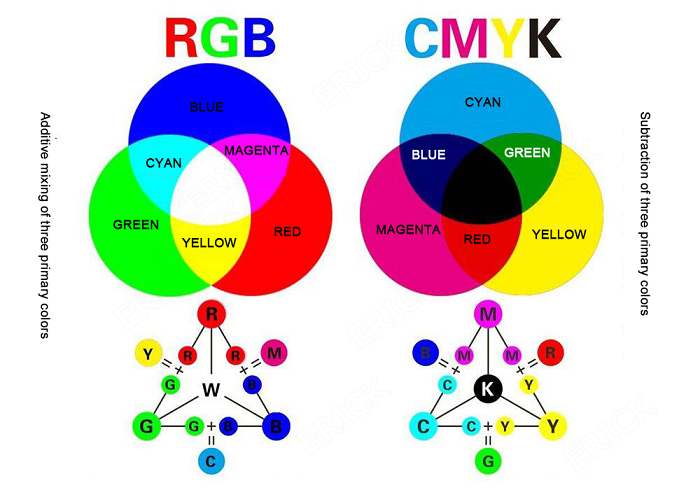

RGB color model refers to the three primary colors of light: Red, Green, and Blue,the three primary color light with different proportions of the sum, can produce a variety of color light, in theory, red, green, blue light can be mixed out of all colors.

In KCMY, CMY is short for yellow, cyan, and magenta. These are the intermediate colors of RGB (three primary colors of light) mixed in pairs, which is the complementary color of RGB

Before going into details, let's look at the following:

In the picture, we can clearly see that the pigment color CMY is subtractive mixing, which is the essential difference, then why our photo machine and UV printer is KCMY?This is mainly because the current level of technology is unable to produce absolutely high purity pigments, tricolour mix is often not the normal black, but a dark red, so special black ink K to neutralize.

Theoretically speaking, RGB is actually the color in nature, which is the color of all natural things that we see with our eyes.

In modern industry, RGB color values are applied to the screen and are classified as luminous colors. This may be because the color purity of light is the highest, so the color that best reflects RGB color values.So we can also classify all visible colors as RGB color values.

In contrast, the KCMY four colors are a color pattern dedicated to industrial printing and are non-luminous.As long as the color is printed on various media by modern printing equipment, the color mode can be classified as KCMY mode.

Now let's look at the comparison between RGB color mode and KCMY color mode in photoshop:

(usually, graphic design will compare the difference between the two colors for rip printing)

Photoshop set up two color modes RGB and KCMY to make some distinction.In fact,the difference is not big after printed out, but if deal picture in RIP with RGB model,you will see the printing result is big difference compare with original photo.

With the development of economy and technology, our lives are becoming more and more convenient, including those who cannot feel the colorful world with their own eyes---Braille is an important factor in showing the civilization of a country. Erick UV printer can help achieve braille alphabet printing.

1. Before printing, we need to edit the image file in Photoshop or Coreldarw, ensure the image file including "Spot channel" of white ink, then save as a TIF format file, as below:

(1).jpg)

2. Import the TIF image file into PhotoPrint and set “print port” as “FILE”, then set the “Spot_1” as “Spot color”, later send the task into a PRT format file on hard-disk.

When your image file ONLY has braille alphabet, no any other pictures or letters, you don’t need to create “spot channel” for white ink in Photoprint, just set “Spot_1” as “Under Color”, same effect.

.jpg)

3. Import the PRT file into PrintExp, we need to set repetition times of white ink as photo below, in order to print white-ink several times to get embossed effect, we suggest 4 or 8 times for white ink here, then click “OK” to print.

(2).jpg)

4. The print effect like the following video inside the link: https://youtu.be/hgGb6OTNqAk

And you can download sample image files of braille alphabet through this link: https://drive.google.com/open?id=1_01HM-JKjcCgr-4ct3lqVeMfxn0cUdOA

Hope it's helpful for you!